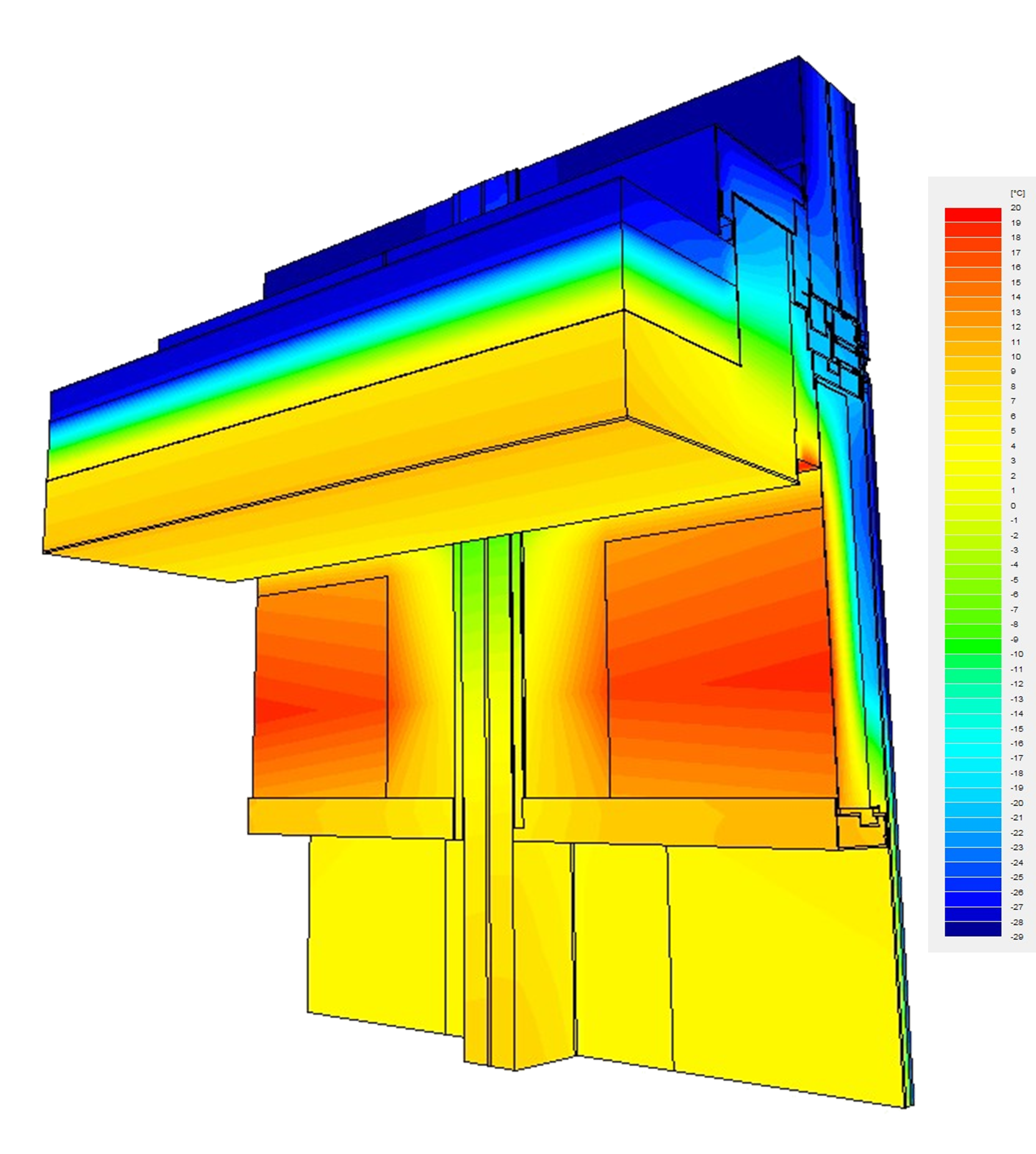

3D model of four intersecting parapet units showing temperature distribution.

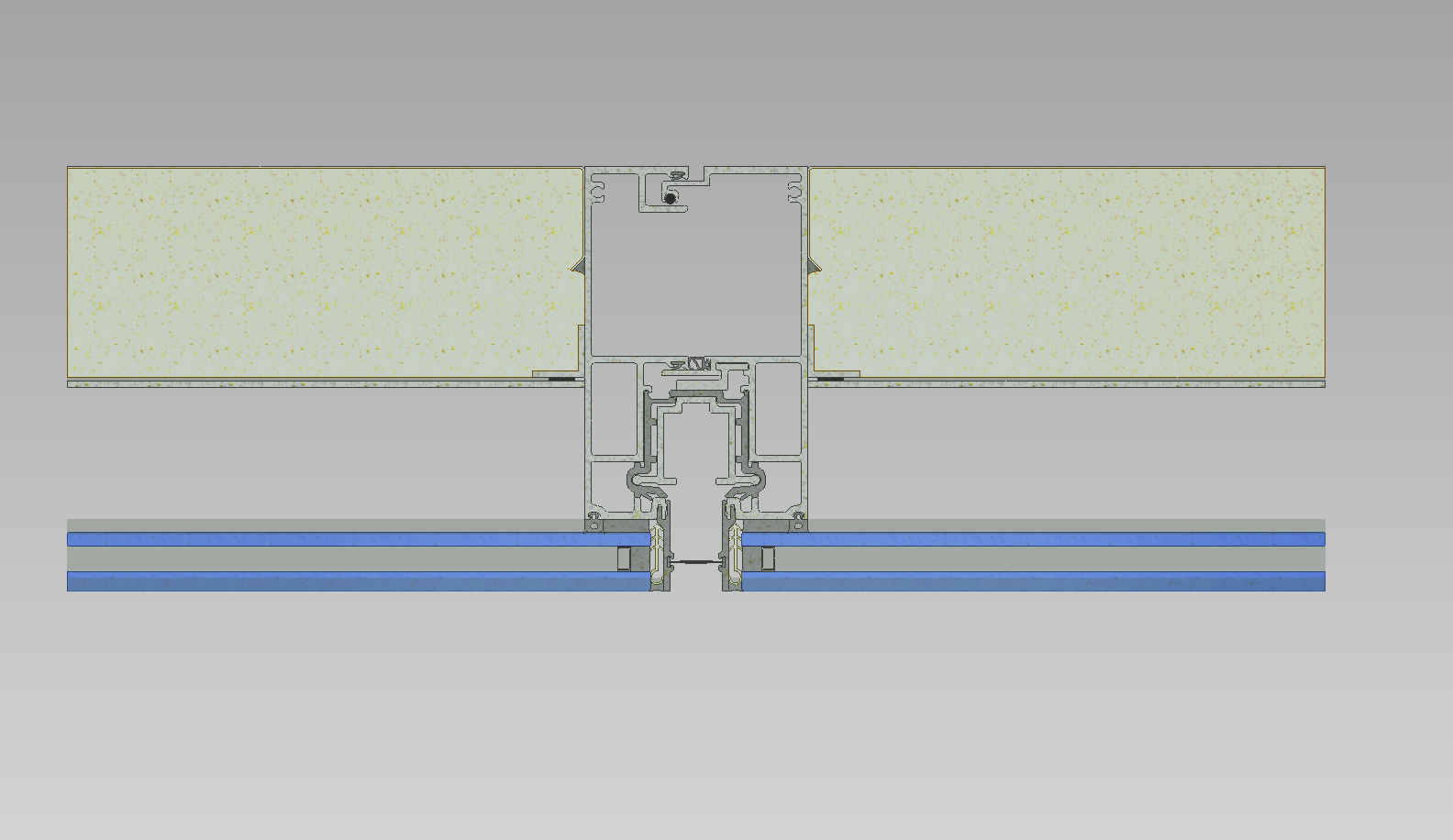

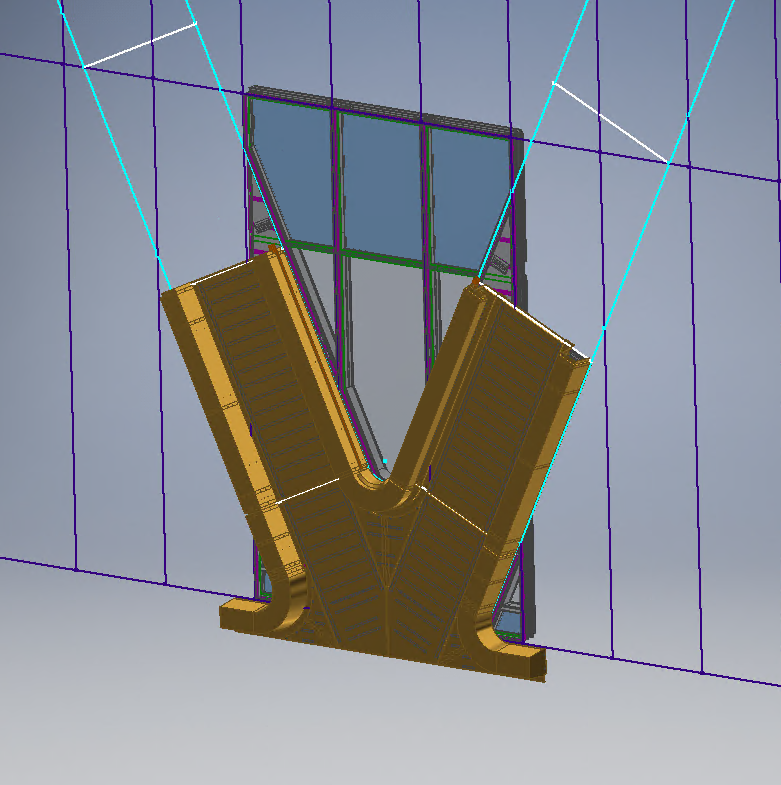

Thermal Analysis

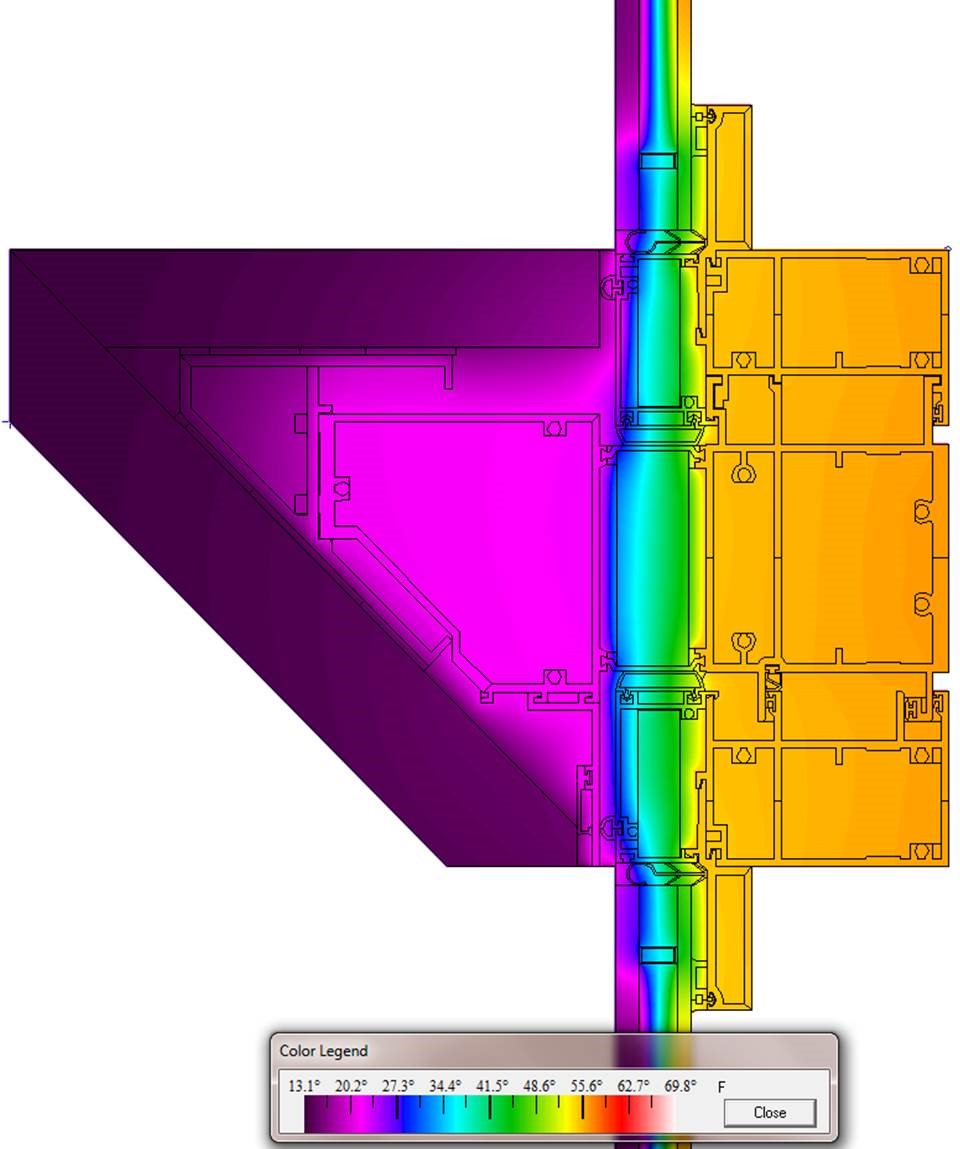

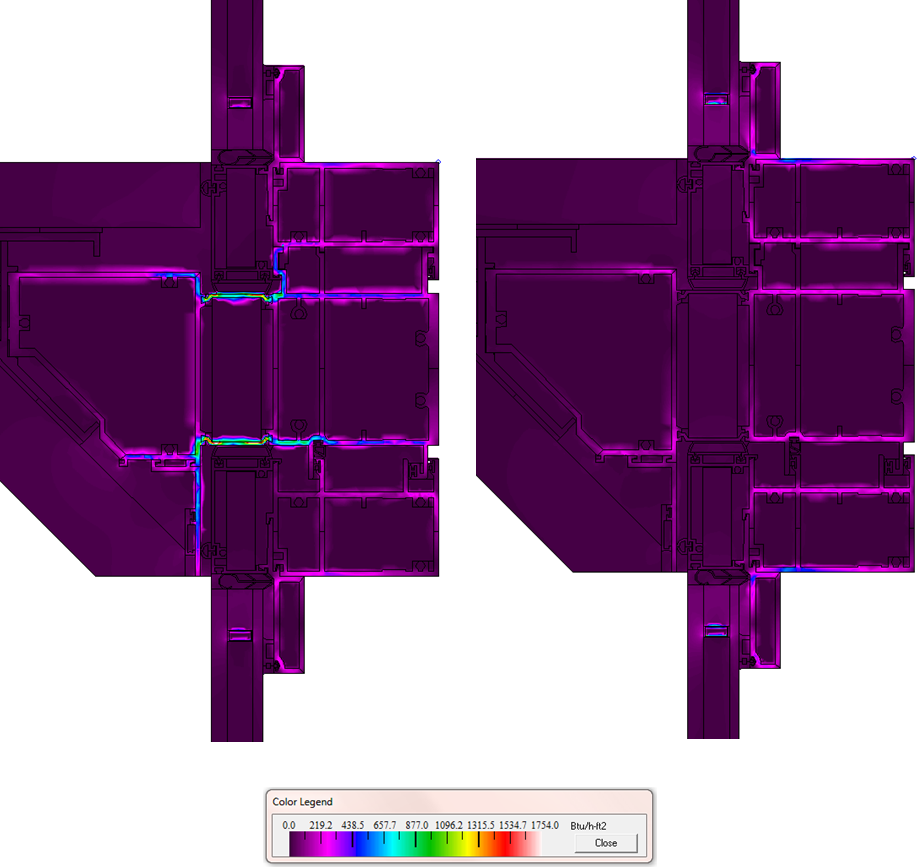

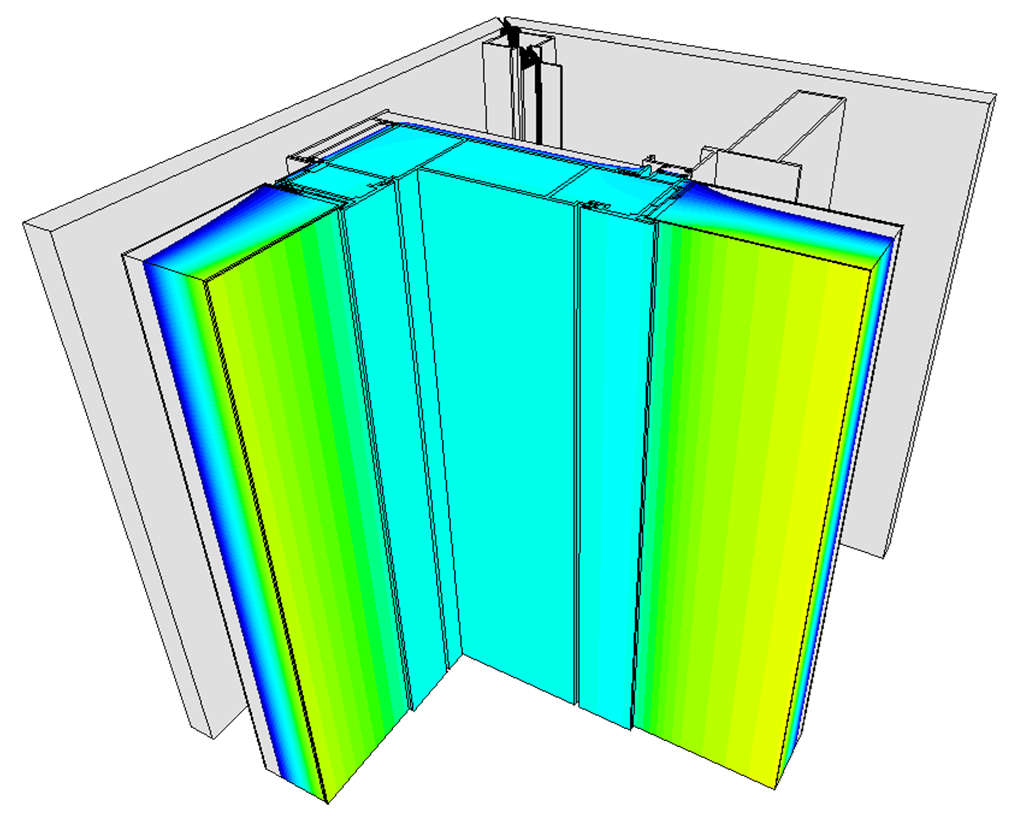

New Hudson Facades provides in-house building physics analysis including 2D and 3D FEA modeling. Building physics teams provide iterative analysis in the conceptual design phase to internal design staff and to the external client to establish overall project energy and sustainability goals. Mechanical engineering staff are certified with NFRC and LEED. Analysis capabilities extend beyond typical energy modeling to include 3D and transient analysis of complex curtainwall systems including transient thermal analysis for evaluation of thermal stress analysis on glass and system components.

2D finite element analysis of a mullion detail showing temperature distribution.

Comparative models showing difference in heat flow characteristics between aluminum connectors on the left and polyamide insulbar on the right.

3D thermal model of a corner unit area with insulation and without aluminum brace.

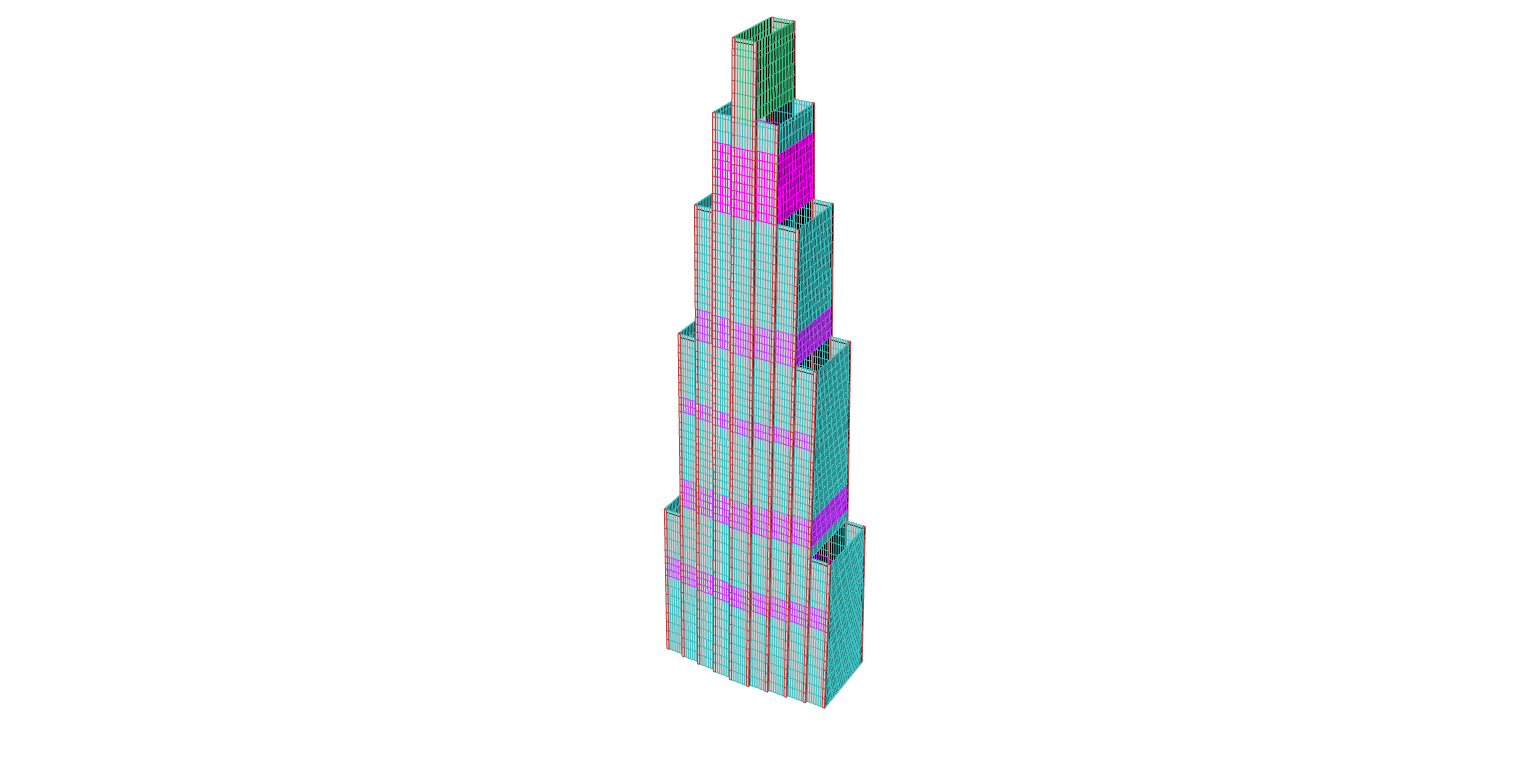

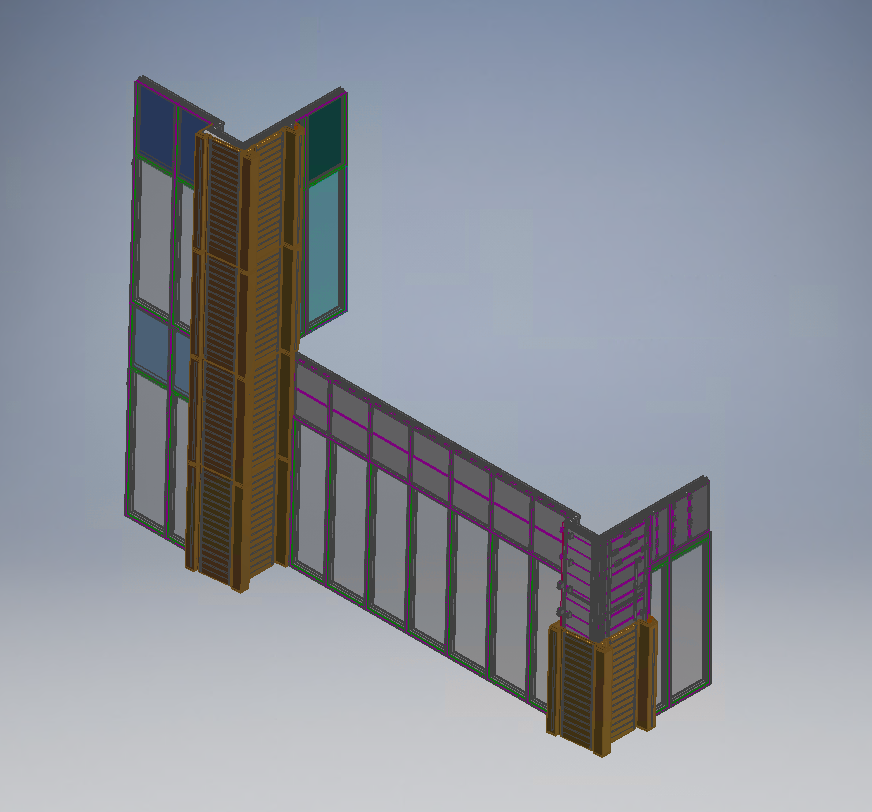

BIM Process

NHF technical teams use a variety of software platforms to model varying unit typologies, generate materials lists, and perform collision detection. We provide constant training so that our teams’ decades of curtainwall experience are augmented by the most current technologies.

Building Information Modeling is a holistic process in AEC industry that guides a digital twin through planning, design, construction and managing of the project. At NHF we use Rhino/Grasshopper to dial down building geometry, AutoCAD/Rhino to create shop drawings, Revit for coordination with other trades as well as design, Navisworks for clash detection and Inventor for fabrication models.

We always review our processes based on the project and new software development available.

In-house 3D rendering of a façade.

Typical early modeling showing a mullion pair at shadow box area.

Parapet and terrace transition building check on the SE corner of levels 16 and 17.

Node study of POHL panels on the 17th level.

Mock-ups

NHF utilizes a variety of mockups to support the design process involved in delivering industry leading curtainwall for world-class buildings. This includes, but is not limited to, early delivery tabletop samples, material selection, and full-scale visual mockups used in the refinement and selection of materials. Mockups support on time product delivery despite supply chain issues. Performance mockups with project specific materials culminate the design assist process to ensure adherence to project specifications. With our proven and patented design, NHF’s first pass testing success is unmatched in the industry. A testing chamber within our production facility allows for quick prototype testing on new products and continuous quality control testing through the life cycle of the project during production.

Performance mockup units (PMU) provide the first opportunity to test engineered design against performance specifications.

Laying the facades during the PMU.

PMUs are typically a two- to three-story full-scale portion of the building that includes critical performance-related details like paint, glass types, reveals, and geometric features.

The NHF team for 3151 Market in Philadelphia celebrates installation of the PMU for this biotech building.